India has seen ultimate growth when it comes to healthcare. 3D printing, a revolutionary technology, has made significant strides in the healthcare industry worldwide, including in India. India has positioned itself as a growing hub in this technology. In India, the adoption of 3D printing in healthcare is accelerating, providing affordable and customized healthcare solutions to a diverse population. 3D printing solutions are fast being adopted by industries ranging from healthcare to automotive due to their advantages in customization, speed, and cost-efficiency. From producing patient-specific implants and prosthetics to bioprinting tissues, 3D printing opens up a new world of possibilities. Here’s a detailed look at the impact of 3D printing in Indian healthcare, its applications, benefits, challenges, and a few notable examples.

What is 3D printing in healthcare?

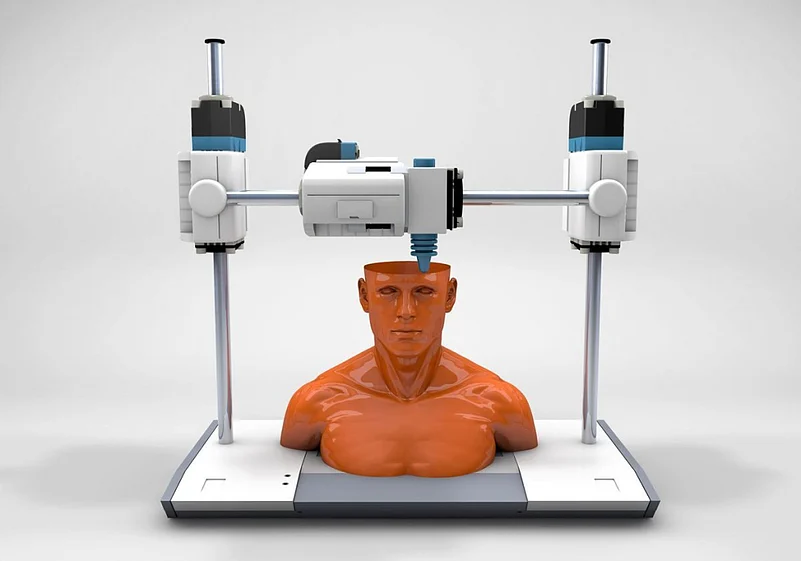

3D printing, also known as additive manufacturing, involves creating three-dimensional objects from a digital file by layering materials in succession. Usually, traditional manufacturing takes a lot of effort in healthcare and requires a lot of manual labour, but 3D printing has made the process much easier, less labour-intensive, and, in some cases, faster and cheaper. The raw materials are ground, carved, and machined until the final product is created. In healthcare, this technology is used to fabricate medical models, implants, prosthetics, and even complex tissue structures. The technology's precision and adaptability allow for highly customized solutions, providing patients with treatments tailored to their specific anatomy and needs.

India’s 3D printing medical device analysis

India's 3D printing medical devices market was valued at $54 million in 2022 and is expected to increase at a compound annual growth rate (CAGR) of 17.8% between 2022 and 2030, reaching $222 million in 2030. According to a report published by Emergen Research, the global 3D printing healthcare market is to be valued at $4,070.8 million by 2027. The market is divided into components, applications, technology, and end users. India's 3D Printing Medical Devices market will expand since 3D printing technology enables the customisation of medical devices, which is increasingly significant in the healthcare industry. Key market participants include 3D Life Prints, Osteo3d, Ayushman3D, Anatomiz3D Medtech, SLM Solutions, EOS, and others. According to a report, the demand for 3D printing is high in healthcare because of the reduced waste generation during the production of medical devices and implants.

The growth of the 3D printing medical device market in India is being driven by multiple factors that include the increased adoption of advanced manufacturing technologies by healthcare providers, the rising prevalence of chronic diseases and the need for personalized medical devices, and increasing patient and healthcare professional awareness of the benefits of 3D printing technology. The usage of 3D printing technology in the Indian medical device business has a substantial impact on the country's entire 3D printing market. With rising demand for individualized medical devices and increased adoption of innovative manufacturing technologies, the 3D printing medical device market in India is expected to grow further in the coming years.

A brief past and future of 3D printing in healthcare

Around 150 years ago or less, the first evidence that humans were on the right track in terms of 3D printing came in the 1860s, when Francois Willeme, a French artist, devised the "photo sculpting" method. This included photographing (or drawing) an object from several angles and then using those photographs to create a 3D depiction.

A hundred and some years later, in 1985, an American from Colorado named Chuck Hall developed the first solid imaging technology, often known as stereolithography. This was the initial stage in the development of the 3D printer. In 2000, the healthcare business began employing 3D printing, and a year later, the first synthetic scaffolds for the human bladder.

The healthcare industry began employing 3D printing in 2000, and the first synthetic scaffolds for human bladder tissue were manufactured the following year. In 2008, the first 3D-printed prosthetic limb was created. Since then, 3D printing in medicine and healthcare has advanced significantly. Blood vessels were 3D bioprinted (a method that combines living cells and biomaterials) in 2009, while 3D-printed human liver tissue became commercially available in 2014. Scientists began bioprinting hearts and lung sacs in 2019.

Recent news from SPARSH Hospitals revealed that the prominent hospital opened India's first on-site sophisticated 3D printing studio at its Infantry Road facility. The new facility offers 3D printing for orthopaedic and personalized medical care, with all services available under one roof, from scanning to final customizable models. As part of its continued investment in cutting-edge technology, the hospital displayed 3D printing technology via a virtual reality system and an advanced robotic system.

According to Dr Sharan Shivaraj Patil, Chairman and Chief Orthopaedic Surgeon, at Sparsh Hospital, “Following the deployment of the robotic system, we are now taking a significant step forward with our advanced 3D printing facility, which reinforces our focus on technology, skill, and experience. A technologically advanced 3D printing lab will revolutionize tailored healthcare treatment in India. It will allow us to create personalized prosthetics and implants, as well as produce surgical models that are precisely tailored to each patient's specific anatomy."

According to a report, at Fortis Mumbai, cardiac surgeons utilize 3D-printed copies of patients' hearts to plan difficult treatments. Similarly, Apollo Hospitals and Anatomiz3D Medtech have teamed to design and build hospital 3D-printing facilities in India, allowing doctors to visualize and manufacture implants for complex surgical procedures.

Development of 3D Printing in Indian Healthcare

Prosthetic legs designed by IIT Guwahati: According to a report, IIT Guwahati researchers have created an economical prosthetic limb developed specifically for Indian circumstances. It is appropriate for uneven terrain and accommodates Indian postures such as cross-legged sitting and deep squatting. It is also adaptable to accommodate different age groups and phases of prosthesis use.

IIT Bombay: According to a report published in the Times of India, about Jaipur Foot, which has helped millions of disadvantaged people walk, and is getting a digital upgrade. Thanks to a Google grant and the expertise of IIT-Bombay, three-dimensional (3D) printers will manufacture their prosthetic sockets one layer at a time. Also, 200 amputees who have used the Jaipur foot for years will transition to the 3D-printed prosthetic.

Apollo Hospital: A patient who met with a traumatic road accident was sent to the Apollo Hospital, where the doctors team, in Navi Mumbai had to guarantee the best possible cosmesis without requiring significant intraoperative manipulation of the skull base repair. The patient's brain was allowed to recover for several months before the scheduled Cranioplasty. As a result, 3D-printed titanium implants were chosen since they precisely matched the contour of the patient's skull. On January 9, 2019, the patient underwent Cranioplasty with the implant, and he recovered quickly and was discharged three days later.

Benefits of 3D printing in Indian healthcare

3D printing is revolutionizing Indian healthcare by offering several benefits. It enables the creation of highly customized prosthetics and implants, perfectly tailored to individual patient needs. Additionally, 3D-printed anatomical models provide invaluable tools for surgeons to plan complex procedures and practice techniques, leading to improved outcomes. 3D printing reduces the cost of production, making treatments and medical aids more affordable. Furthermore, 3D printing facilitates the accessibility of medical devices, particularly in remote areas with limited healthcare infrastructure. This technology holds the potential to significantly enhance patient care and treatment options across India.

Challenges and opportunities:

Despite its rapid growth, the Indian printing sector confronts problems such as high beginning costs, restricted local output, and a shortage of experienced workers. The market relies heavily on imported materials and technologies. However, government initiatives like the Make in India program seek to increase domestic production and minimize dependency on imports. Simultaneously, 3D printing costs continue to fall as technology progresses and economies of scale emerge. The rising affordability of printers and materials allows for more widespread use across borders.

Why India is an attractive destination for 3D printing

India is emerging as a prominent destination for foreign patients seeking advanced 3D printing-based medical treatments. Known for its expertise in customized prosthetics, implants, and surgical models, Indian healthcare providers leverage 3D printing to offer tailored, cost-effective solutions. For example, 3D-printed prosthetic limbs are becoming a popular cost-effective choice in India. Affordability and a vast segment of highly qualified doctors in India make India a popular choice for medical tourism. Hip replacement in the United States can cost between $30,000 and $50,000, while the identical procedure in India can cost between $5,000 and $9,000. Also, The US is the leading export market for Indian 3D printers, followed by Indonesia, Vietnam, and Brazil. This demonstrates India's potential to become a major worldwide player in the additive manufacturing industry. With this, the 3D printing market to grow at an impressive CAGR of over 20% between 2023 and 2030.

3D printing has already proven its worth in Indian healthcare, improving surgical outcomes, making prosthetics and implants accessible, and providing rapid responses during medical crises. Despite some challenges, the possibilities of 3D printing continue to expand, promising a future where custom, on-demand medical solutions are available across India. With continued investment and innovation, 3D printing could indeed become a cornerstone of accessible, personalized healthcare in India.