Lighter than its predecessors, but with more freight carrying capacity, the railways first indigenously manufactured aluminium goods train rake was flagged off from Bhubaneswar in Odisha on Sunday.

Manufactured in collaboration with Besco Limited Wagon Division and aluminium major Hindalco, it also has a lower carbon footprint for every 100 kg of weight reduction in wagons, the railways said. The lifetime carbon saving is eight to 10 tonnes and this means, savings of more than 14,500 tonnes of carbon for a single rake, it said.

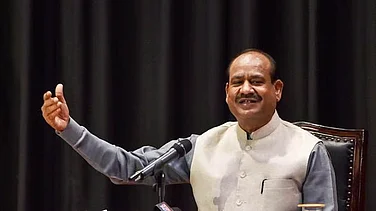

Flagged off by Railway Minister Ashwini Vaishnaw, the rake is 180 tonnes lighter than existing steel rakes, resulting in increased speed and lower power consumption for the same distance, the national transporter said. It can carry 180 tonnes extra payload per trip over conventional rakes and being corrosion resistant, will reduce maintenance costs, it said, adding that fully lock bolted construction was used to built these wagons with no welding on the superstructure.

The railways said that the new rakes have a 80 per cent resale value and a 10 year longer lifespan as compared to normal ones. But the manufacturing cost is 35 per cent higher as the superstructure is all aluminium, it said.

The iron and steel industry consumes a lot of nickel and cadmium which are imported. So proliferation of aluminum wagons will result in less import and at the same time, this is good for the domestic aluminum industry, an official said.

(With PTI inputs)